| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CIF |

| Min. Order: | 1 Set/Sets |

| Delivery Time: | 25 Days |

Model No.: FY-828 glazed/840/900

1 Roller material: high grade No.45 forged steel, plated hard chrome on the surface of roller with thickness 0.05mm

2 Active shaft material: high grade No.45 carbon wrought steel at diameter 75mm

3 Cutter blade: Cr12 mould steel with quenched treatment

4 Eletric elements: control systerm with PLC model S7-200,Siemens transducer with ABB control panel with TP 170, Siemens it can input 10 sets of spec at one time

5 Oil tank model of hydraulic systerm: CB-E310

Material of rollers:45# steel,roller surfaces polishing, hard plating .The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

As a professional manufacturer,we can make the Three Layer Roll Forming Machine by customer`s demand, with a profile drawing and thickness, we can do design the machine quickly.Until now,we can do many kinds of roof panel machine,such as trapezoidal sheet making machine, corrugated sheet mnaking machine, glazed Tile Making Machine, C Z Purlin Roll Forming Machine and so on.Here is some profile drawings for you reference.

We can also customize according to your needs,any Other requirement please send inquiry to us.

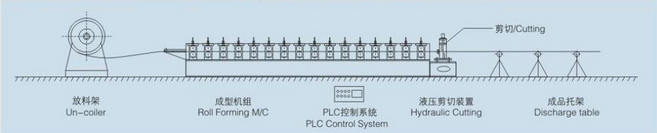

The chart of process:

manual uncoiler - roll forming machine - computer control system - hydraulic control system - cutting system - output table

Double deck roofing roll forming machine parameters

<1> Step of forming roller : 13steps +11steps

<2> Diameter of shaft (solid shaft) : 74mm

<3> Material of shaft (solid shaft): (high grade) 45# Steel, quenched and tempered

<4> Razor blades material : Cr12, quenching 58-62 °

<5> Power of main motor : 3KW

<6> Reducer : 5# cycloid reducer (high grade)Voltage : 380V/50Hz/3phase

<7> Motor power of hydraulic station : 3kw

<8> Voltage: 380V/50Hz/3phase

<9> Line speed : about 9 m/min

<10> Appearance size : 8.2m (length)*1.3m (width) *1.3m (height)

<11> PLC : DELTA(TAIWAN)

<12> Frequency converter : DELTA(TAIWAN)

Manual Uncoiler

Usage:It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand.

Passive uncoil pulled by roll forming system

Roller

Material of rollers:45# steel,roller surfaces polishing, hard plating ,

The polished surface and the heat treatment towards the molds also can keep the molding

plate surface smooth and not easy to be marked when it is being stamped.

Coil Feeding Part

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working

Cutting device

Material of the cutting:Cr12Mov with quenched treatment.It can decide cut panel dimension according to the hydraulic drive and PLC computer control system.

About our company:

Cangzhou Feiyang Machinery Co.,Ltd is a company specialising in the filed of cold roll forming machines and metal sheet processing.We have been establishing and keeping good business relationship with more than 70 countries of worthy clients all over the world, mainly locating in East Europe, Middle East, South and West Asia, Africa and South America. We are proud of our own professional team with more than 18 years` experience in customized design and manufacture, installation and test, technical solution and after services. All the machines are with international quality standards and great after-sales services.

Main product catagories

Roof And Wall Panel Roll Forming Machine,Hydraulic Decoiler And Curving Machine,Bending Machine And Cutting Machine,C/Z/U Purlin Roll Forming Machine,Door Frame Roll Forming Machine,Stone Coated Roof Production Line,Floor Deck Roll Forming Machine,and various kinds full-automatic cold bending roll forming equipment.We do firmly believe :technological innovation ,making every detail of the product perfect is our ambition ever.

Any other questions please send inqury to us

Product Categories : Three Layer Roll Forming Machine